Jamie Matusow, Editor-in-Chief05.31.22

The birth of tubes as easily squeezable and collapsible packages for dispensing products from paint to glue to cosmetics—and perhaps most notably, toothpaste—was recorded in 1841, when American artist John Goffe Rand invented a pliable metal tube to effectively hold paint. (HistoryofCosmetics.net; Wikipedia)

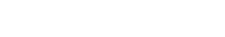

Almost a half-century later, in 1889, Johnson & Johnson was the first major company to package toothpaste in a tube, when they introduced their first consumer product, Zonweiss, in a collapsible metal tube. Soon after, a Connecticut dentist started selling toothpaste in lead tubes in the 1890s.

A metal shortage caused by World War II put an end to tubes made of tin and lead, and packaging producers moved to aluminum and plastic. Most toothpaste tubes have been made from sheets of plastic laminate, which is usually a combination of various plastics surrounding a thin layer of aluminum that works to protect the taste and formula of the product inside.

Now, in this age of packaging sustainability consciousness and mandates, the mixed material composition of toothpaste tubes makes them difficult to recycle, and cosmetic industry suppliers and brands are again in the midst of finding new solutions.

Tubes are increasingly available in an array of materials from plastics to aluminum to paper to sugarcane bioplastics; in sizes from minis to economy; shapes from round to oval (and beyond—read on); and topped with an array of cap styles.

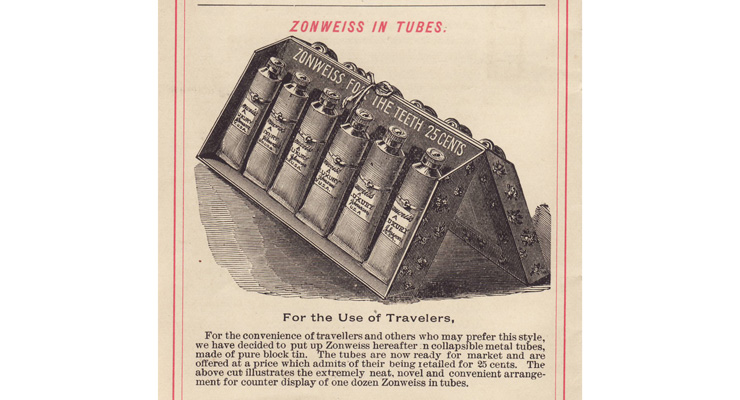

With their many benefits, including hygienic protection, ease of use, cost-effectiveness and decorative options, tubes have become the preferred packaging not only for many oral care products, but also for cosmetic items from eye shadow to lip balm to hair treatments.

A Bright Future for Tubes

At the end of 2021, research from Future Market Insights (FMI) showed that the global cosmetic tubes market was expected to reach a valuation of $2.4 billion for the year. With rising demand for their use in makeup and skincare products, FMI predicted that the overall sales of cosmetic tubes would increase at 4.6% CAGR between 2021 and 2031.Cosmetic tubes offer various advantages over conventional packaging solutions, say FMI analysts. They are versatile, easy to use, lightweight, preserve moisture, and provide effective protection against contamination from various environmental factors. Most plastic tubes are considered safe as they do not interact with the contents within the tube. R&D success has also led to improved flexibility, decorative techniques and labeling—and new and advanced versions of materials from aluminum to paper.

Manufacturers are now focusing on developing cosmetic tubes from recyclable and biodegradable materials, says FMI, with some of the leading cosmetic tubes manufacturers moving away from plastic use to recycled materials. Advanced decorating techniques are providing new visual interest to tubes as well—from vintage vibes to elegant renderings and bold hues.

Growth Areas

Tube suppliers we spoke with for this article report an uptick in production, and in many cases cite the on-shoring trend, which can ease certain supply chain difficulties. But growth in the tubes market has been ongoing.Viva has seen steady growth every year for the past decade, reports Melanie Gaudun, business development manager.

Plastic squeeze tube production and decoration currently represent the larger part of second- and third-generation owned-and-operated JSN. Sandy Nagel, vice president, JSN, tells Beauty Packaging, “We are seeing modest but steady, consistent growth in our market. In addition, on-shoring continues to add to domestic manufacturing demand.” Nagel says that it’s not only Made in USA that sets them apart from their competitors, but that “the footprint of a whole package is advantaged because manufacture of tubes, decoration and closure can be accomplished timely and effectively in one location.”

Growth with a few Covid-19 related blips and re-focuses were the case at Neopac, where Cornelia Schmid, marketing manager, told Beauty Packaging, “During the pandemic we saw stable growth, but travel retail and luxury cosmetics went down and there was a noticeable pivot toward less expensive brands. However, we saw increases in other areas, including sanitizers and medical brands.”

Stephane Beauchemin, vice president of sales & marketing at Plastube, sums it up, saying, “The fact that tubes require less plastic than bottles for the same capacity during the manufacturing process will contribute to increase the demand for tubes.”

What’s New in Tubes?

As testimony to just how far tubes have progressed, we asked a number of leading tube suppliers in the cosmetic industry to tell us about their most recent launches, the latest trends they’re seeing in the industry, what brands are looking for—and ultimately, what consumers are demanding of their packaging in this space.A Groundbreaking First

Albéa provides plastic and laminate tubes, printing expertise, caps and applicators, and an extensive range of recycling-ready, paper-based, PCR and bio-based tubes.In 2020, L’Oréal and Albéa launched the “groundbreaking,” first paper-based cosmetic tubes designed to replace L’Oréal plastic cosmetic tubes in the midst of growing environmental concerns.

In March of this year, LyondellBasell, Albéa Tubes and L’OCCITANE en Provence launched what they again called “groundbreaking” cosmetic tubes and caps for L’OCCITANE en Provence’s Almond range. Created to support the circular economy, the packaging is made by Albéa Tubes with CirculenRevive polymers from LyondellBasell.

A member of the Ellen MacArthur Foundation, Albéa manufactured the actual cosmetic tubes and caps for L’OCCITANE en Provence. Albéa has pledged to make all of its tubes recyclable by 2025, and increase the use of post-consumer recycled resins.

L’OCCITANE en Provence, which has signed the Ellen MacArthur Foundation Global Commitment, has said they will “cultivate change” at every level, starting with the sustainable design and production of their packaging.

Richard Roudeix, LyondellBasell senior vice president of Olefins and Polyolefins for Europe, Middle East, Africa and India, said, “We are excited to work with Albéa Tubes and L’OCCITANE en Provence on this project and to contribute to circular cosmetic packaging solutions. “Our CirculenRevive products, which are part of our Circulen product range of sustainable solutions, are polymers based on advanced (chemical) recycling technology from our supplier Plastic Energy who converts end-of-life plastic waste streams into pyrolysis oil feedstock.”

Gilles Swyngedauw, VP of sustainability and innovation at Albéa Tubes, says, “The Almond Shower Scrub is the holy grail in terms of responsible packaging today. The tube and cap are designed for full recyclability and made of 93% recycled polyethylene (PE) content. On top, both are made of PE for higher-quality recycling, confirmed as recycling-ready by recycler associations in both Europe and the U.S. This packaging is in effect closing the loop, and that’s quite a breakthrough!”

From Tube to Cap

Many tube manufacturers also manufacture closures, for complete, seamless packages.Closure manufacture is a valuable asset at JSN, which began developing the Disc Top dispensing closure more than 40 years ago. Tube production began five years later. While the company now purchases tube closures “from the most reputable sources,” says Nagel, “we also produce in-house closures to complement our own tubes. This expedites special colors, special additives, and general lead-time responsiveness.” Another of JSN’s capabilities is the manufacture of custom closures—in proprietary designs, logos, and high-end nail polish closures. Conventional deco includes offset, silkscreen and hot-stamp.

In tubes, JSN has been utilizing sustainable polyethylene resin from sugarcane for several years. “It is certainly our first recommended “go-to,” says Nagel, “and is readily accepted in the personal care industry. Sugarcane resin also has the great advantage of not hindering the decoration process.”

Nagel says PCR is used routinely in dark colored personal care caps/closures. She explains, “PCR in a flexible tube package is more complicated due to the thin sidewalls and customer preference to avoid product contact with PCR layers. Commercially available PCR is continuing to improve, but color variation and imperfections are still a challenge. We are seeing complete redesign of some package art to accommodate [this].”

Recently, JSN added production of plastic co-ex laminate tubes which allow greatly expanded decorative options on white and metallic substrates. In addition to expanded deco possibilities, this product also offers more effective inventory warehousing to permit shorter lead-time on final tube production—an attractive feature for some users, explains Nagel.

Berry Global provides laminate and extruded tubes, plus matching closures, in a broad range of size styles and colors to provide the complete tube package. They offer a wide range of “brand differentiating, premium decoration options.”

Vali Braselton, marketing manager, Consumer Products North America, Berry, tells Beauty Packaging, “Because there are many paths to sustainability, we offer our customers a variety of circular packaging options for tubes to help them meet their sustainability goals. Our size, scale and expertise translate into solutions that include recycled content, reduced carbon footprint, renewable material and improved recyclability.”

Berry recently launched bio-resin polyethylene tubes made from HDPE sugarcane, and their single-substrate HDPE laminate tube with HDPE closure has been recognized by the APR. In addition, their laminate tubes are offered from “pellet to pallet.” This means Berry extrudes, forms, decorates and caps all tubes in their Evansville, IN facility, resulting in one of the “lowest carbon footprints in the industry,” according to Braselton.

Berry recently introduced a low-profile tube, available with a matte or glossy cap, that reduces carbon footprint by using less material—specifically 24% less material in the cap and 16% less in the shoulder. The tube can be made with PCR, is made from 100% PE for improved recyclability and can be decorated just like any other laminate tube, says Braselton.

PE, COEX and Polyfoil Tubes

Neopac manufactures PE, COEX and polyfoil tubes ranging from 10-50mm. Among other solutions, Schmid says “Our EcoDesign range comprises tubes that are lightweight and utilize recycled content or bio-based materials. In addition, Neopac has patented a recyclable mono-material-barrier tube, Polyfoil MMB, that was recently approved as recyclable by the U.S. Association of Plastic Recyclers.For specialty cosmetics, Neopac offers tubes with pumps, applicators and nozzles, and also child-resistant options for concentrates and cosmeceuticals. They also have a PE/PP cap in-house production for screw and flip-top caps.

Neopac’s Stylo Pipette Tube, utilized by skincare company Filorga, incorporates an innovative pipette applicator allowing for dispensing of Filorga’s Skin-Unify radiance fluid directly onto the skin. The precision dispensing adds new levels of comfort and hygiene.

The Stylo tube’s aesthetically appealing ring ensures correct discharge, and offers added product protection. An arrow pictogram helps consumers intuitively understand how to turn the ring. The cone-shaped cap safeguards the applicator, while Neopac’s polyfoil barrier laminate ensures ample formula protection.

Overall, the tube’s premium look, eye-catching conical shape, transparent cap and enticing pipette applicator help Filorga’s Skin-Unify radiance fluid stand out in a crowded, competitive space.

Tubes with In-Mold Labels

Viva specializes in manufacturing unique polypropylene (PP) tubes, applicators and caps, with in-mold label decoration. The company is vertically integrated, with tubes, closures and decoration all made under the same roof in Toronto, serving North and South America. Viva also has a production facility in Warsaw to serve the European market, and a plant in Hong Kong, where their design team works on new developments.According to Viva’s Gaudun, the company’s injection-molded tubes have a number of unique benefits, including a smooth, resilient profile that retains a round, wrinkle-free shape throughout its lifecycle; a mono-material design compatible with the rigid PP recycling stream per the APR Design Guide for Tube Recyclability; and highest content PCR, up to 90% in tube and cap combined.

The beauty of in-mold label decoration, says Gaudun, is high definition, shoulder to crimp artwork with 360-degree coverage; and options for spot matte, spot gloss, foil effects and velvet soft touch finishes. Viva also designs their flip-top caps to be oriented with the customer’s artwork.

One of the largest areas of growth at Viva is in tubes with PCR content. Viva can include up to 87% PCR in the tube (including sleeve, neck and shoulders) and 100% in the cap, for a combined total of 90% PCR, says Gaudun. Viva has seen steady growth every year for the past decade—and reports “extra growth” in their smallest diameter tubes (0.34 oz. to 0.75 oz.), tubes with applicators, and tubes with their highly tactile velvet soft touch finish.

For more than 50 years, CTL-PACK has provided “the highest quality plastic tubes in the U.S. & European markets.” According to Andy Olsen, vice president, sales & marketing, they work with customers to develop high-end plastic tubes, premium decoration capabilities and continuous innovation for both extruded and injection molded round and elliptical plastic tubes. In the U.S., they manufacture injection molded PP in-mold-labeled tubes. According to Olsen, this technology “delivers superior decoration, improved supply chain performance (MOQ’s 5/m) and a winning sustainable package with a uniform all-PP package.”

CTL PACK’s in-mold-label tubes deliver premium decoration using digital and flexography printing technology. “This allows for marketers to decorate on a flat substrate versus decorating the tube after the tube is made.” The company’s IML tubes are 100% polypropylene making them recyclable, and they can add PCR “to further the sustainability value.”

Olsen says the company recently developed tubes that “showcase our ability to deliver serialization.” In this example, CTL printed 3 different images of Paris’s skyline. When placed together on the shelf, the 3 different decorated tubes produce a collage-like image. This ability can be applied to various patterns, colors, names or images to create a larger picture when viewed from a distance.

Full Aluminum and Laminate Tubes

Montebello offers both full aluminum tubes and laminate tubes. Steven MacPhail, vice president sales & marketing, says, “For the cosmetic industry, aluminum tubes offer the highest barrier property, and specialty head styles for controlled application as well as the vintage look.”Small to Medium Runs with Deco & Digital Printing

Plastube has been manufacturing and decorating tubes aimed at the cosmetic, veterinary, pharmaceutical & food industries in North America since the start of the company in 1963. Beauchemin says Plastube “is the partner of choice for fillers and manufacturers of products packaged in tubes for small to medium size runs, and offers a multiple variety of decoration solutions including digital printing that delivers high-quality printing.”Plastube recently produced The Koyal Beauty Gentle Gel Face Wash 60ml. This is one of the first COEX-PCR tubes printed by Plastube using their digital printer, and Beauchemin says, “The result was astonishing!”

From Filling to Shipping

Norden Machinery offers tube filling systems, cartoning and shipper box packing solutions for tubes. The portfolio ranges from speeds between 40-1,000 tubes/min. Ida Sigvardsson, marketing specialist, Norden Machinery, tells Beauty Packaging, “We work with customers using all kinds of tubes, plastic, laminates, metal and sustainable tubes.”Norden Machinery recently developed a paper-based tube, but it was not without challenges, due to the very low plastics content. “Still,” says Sigvardsson, “the pressure tests show that the laminate structure of the paper fiber separates before the sealing breaks. The customer needs to be able to trust that the tube has the same durability properties as an average tube. This was the challenge, and we managed to solve it with a good outcome.”

Benefits of Tubes

As mentioned, the popularity of tubes is increasing due to their many benefits. Suppliers mentioned some of the chief advantages for brands and consumers.Tubes are fundamentally convenient and versatile, says Viva’s Gaudun. “To start with, they are highly portable, shower-friendly and travel-friendly. Most sizes fit nicely into the average person’s hand. It’s almost therapeutic to squeeze a tube.”

Viva’s tube options include a wide variety of diameters, lengths, orifice sizes and applicator attachments, in sizes ranging from 0.34 oz. to 15.5 oz. Tubes can include barriers to support a wide range of formulations, with custom colors in the resin and in-mold label (IML) decoration to match any other existing packaging.

In addition, says Gaudun, “Viva can design your tubes to meet the current requirements of the rigid PP recycling streams, and include up to 90% PCR in tube and cap combined. She cites a 2020 Life Cycle Analysis, in which Viva’s PP tubes show over 50% lower impacts in the top three categories that contribute to over 80% of the overall environmental impact of plastic tubes: global warming fine particulate matter formation, and human non-carcinogenic toxicity.

At Neopac, Schmid, says among other benefits, tubes offer a superior “packaging to product” ratio compared to bottles. “They have attractive ‘good-to-empty’ rates for viscous products, creams and liquids. Tubes also offer a wide array of printing and decoration options, including various combinations of offset, silk-screen, flexo, digital printing and hot-stamping.

In addition, Schmid says high-barrier tubes can provide “longer shelf life and exemplary protection against air, moisture or light.

Montebello’s MacPhail tells Beauty Packaging that tubes continue to have a place in all product categories, noting that collections can be in haircare for colorants or large format tubes for shampoo. “Skincare and high-end derma require tubes to carry the expensive formulas and give some directional and controlled application,” says MacPhail. On the other hand, “Tubes offer a variety of smaller formats and are extremely portable. In the tube industry we continue to explore different materials to improve sustainability.”

When it comes to sustainability, Beauchemin says Plastube tubes will generally weigh about 50% less than bottles for a comparable capacity making them a good sustainable option. Printing digitally on PCR tubes is the most sustainable option offered by Plastube because there is no ink purge at the end of the production with digital printing.

CTL’s Olsen says “Tubes offer a great solution to brand owners looking for a packaging solution that delivers on fit, form and function. There can be a multitude of specs to choose from with mono-layer tubes, multi-layer tubes and various barriers and decoration capabilities. Tubes are inverted allowing consumers to evacuate the majority of their products by the nature of gravity.” He says tubes are also easy and fast to fill having a large opening [which can be] filled before being crimped and packed into shippers.

Norden Machinery’s Sigvardsson points to tubes’ benefits around ease and hygiene.

“Tubes are often a preferred packaging solution for cosmetics, and personal care products,” says Sigvardsson. “It is a hygienic and easy way to handle your product. You can apply the content (i.e, sunscreen or moisturizing cream) with only one hand, it is easily stored, and it is possible to pack large volumes at high speeds.” She explains that as the tube contains less packaging materials than an equivalent type of packaging, it is very efficient. Finally, she says, “the tube is a type of packaging that allows squeezing every bit of the content out, which means that no residue is left in the packaging, providing better value for the consumer, and no waste.”

What Types of Tubes are Brands Looking For?

From ease of dispensing to innovative shapes and sizes, to sustainability, here’s what suppliers say brands are looking for in today’s tubes.Innovative Shapes

At The Penthouse Group, Richard Esterbrook, director of sales, tells Beauty Packaging they have recently noticed that customers are looking for more interesting shapes in tubes, rather than the traditional round or oval shapes. While some tube vendors are able to injection mold a tube neck in different shapes like square, triangle, etc., the tube sleeve itself is usually not changed much as a result of it. However, through their “Blow Tube” innovation, Yoshino can utilize their bottle blow molding expertise to radically change the shape of the sleeve itself as well. (The Penthouse Group is the sales and customer service representative of Yoshino in North America.)The Penthouse Group has also responded to the eco-friendly call with Yoshino’s low profile flip top closure. Esterbrook says, “Sometimes simple changes to packaging can have a big impact on the environment over time.” One such idea that Yoshino commercialized in the Japan market was to minimize the height profile of a standard flip top closure, essentially making it shorter and saving cost and the amount of plastic resin used. He says, “Our hope is that by introducing this concept to the U.S. market, we can introduce a new trend so that eventually most flip top closures are transitioned to the low-profile type.”

Norden Machinery’s Sigvardsson also speaks about new, innovative shapes for tubes. She says, “Some brands choose to fill their product in an oval tube, which gives an exclusive impression and a good grip in the hand. There is also Design-a-Seal, where the end of the tube can be in a bow or arched shape, making the tube look spectacular and [different].” She says one of the most creative applications that they have worked with is a foot crème with the top of the tube shaped as toes. She also cites examples of kids’ tubes where the top of the tube is shaped as a cat with ears, making it look cute and funny. “All this was possible because customers made a special request to Norden, and a special tooling was created so that the tubes could be produced in such a special design,” says Sigvardsson.

Size, Dispensing and Sustainability

As far as sustainability, Sigvardsson says, “Often, a mono-material tube is preferred, due to its recyclability. It is also popular with paper laminate and bio-plastics tubes.”At Viva, Gaudun tells Beauty Packaging that brands are looking to round out their product lines with different sizes of tubes, options for PCR content, different means of dispensing, and beautiful decoration options. Viva’s deodorant tube, powder tube, scalp applicator tube, and airless pump tubes were all developed to meet specific needs clients had for their product lineups. In addition, on the sustainable packaging front, “Viva tubes include a unique, tried and tested mono-material PP design that is compatible with the current rigid PP recycling stream,” says Gaudun.

Viva recently developed the Head & Shoulders Clinical Scalp Calming Treatment Tube with a custom applicator that includes a longer nozzle than is typically available via a nose. This longer nozzle is able to navigate through hair down to the scalp area, for precision point application of a treatment that is to be applied up to four times a day. The tube comes in a convenient size for travel. The applicator is part of a mono-material design. Both tube and applicator are color-matched to the blue foil artwork, creating a continuous V-shape from the crimp down to the applicator tip, which is visible through the clear cap.”

Plastube’s Beauchemin says many brand owners have made the commitment to reduce their environmental footprint by 20% - 50% by 2025 and as such are looking for greener material. He says Post Consumer Resin remains the most requested material, “which is understandable as it offers the best environmental footprint when compared to other materials.”

Sustainability that doesn’t sacrifice product protection continues to dominate brands’ wish lists, says Neopac’s Schmid. “Our EcoDesign tubes offer strong barrier properties and elaborate decorative options (direct print, not labels) while comprising eco-conscious materials that can hold more than 30% PCR content; fit into existing PE or PP recycling streams (mono-material barrier tubes); be light weighted to save CO2 and plastics; are biodegradable; or have bio-based content.”

At CTL, Olsen says brands are looking for small, medium and large tubes for various products in hair care, skin care, baby care and sun care to name a few. Materials range from extruded tubes (LLDPE, LPDE, MPE & HDPE) to laminate and IML polypropylene tubes. Many brands are looking for sustainable materials like sugar cane-based resin and/or post-consumer resins.

Looking Ahead

It appears clear that tubes will remain a vibrant packaging category for the cosmetic industry due to their many benefits and advances in materials, sizes, dispensing and deco options. But similar to other packaging categories, challenges lie ahead as suppliers continue to meet rising demand.JSN’s Nagel says one of the primary challenges is “to reduce plastic content in plastic packaging via additions in sustainable resins, PCR content, and thin-walling existing packaging.”

At Neopac, Schmid says, “Notably, the challenges we are facing as an industry include the price increase of raw materials, the scarcity of EVOH barrier material in particular, and the availability of qualified pure (food grade) PCR material on the market.”

Aluminum Tubes Led to Success at Summer Fridays

Known for its clean skincare and sustainability messaging, Summer Fridays premiered in 2018, with skincare packaged in aluminum tubes. It was not the norm at the time—but proved to be wildly successful. Beauty Packaging asked brand co-founder Lauren Ireland why they chose this packaging route. She told us:“From the start, we had a very clear vision of launching our first product in an aluminum tube. At the time, very few brands—particularly in beauty—had done it, and it felt really special. The look of a near-empty, crinkled aluminum tube of our Jet Lag Mask became a recognizable part of our brand story, as it quickly took over people’s Instagram news feeds. We believe our product’s unique packaging really helped catapult the success of the brand.

“Of course, beyond the aesthetics of it, an aluminum tube is also recyclable, and sustainability was important to us and to our community. Our first three products—all face masks—were put into aluminum tubes. While we now have a wide product range and therefore a variety of packaging, our aluminum tubes are core to our brand and our long-term efforts of sourcing solutions that are both sustainable and practical.”

Wood-Based Tubes Support ‘Field-to-Face’ Beauty at Bloomeffects

With a heritage in sustainable practices, the Dutch-owned brand Bloomeffects creates products and packaging in sync with their DNA—for a true “field-to-face” beauty experience. Their multitasking Tulip Tint Lip & Cheek Balm is now available in 3 universal shades for all skin tones.Bloomeffects supports circular farming practices through the upcycling of imperfect tulip bulbs that would otherwise be discarded as “waste” and revitalizes them as ingredients in their skincare collection.

The same care is given to their packaging, which tells the brand’s story at first glance. All Bloomeffects product cartons are FSC certified, made from 100% recycled materials, and are 100% recyclable. Tulip Tint packaging is made with PICEA wood tubes made from sawdust from German carpenters and other materials from renewable resources, “resulting in a carbon footprint that is 40% smaller than conventional plastic tubes.” The brand says it is also the first beauty brand to use PICEA in the U.S. Cartons are FSC-certified, made from 100% recycled materials and are 100% recyclable.